CNC Machined & Engineered Components

- Teak Toe Rail

- Salon Custom Cabinetry

- Teak Ladder Steps

- Arch Cabin Doors/Trim

- A/V Custom Compartments

- Window Trim/Lamberkins

- Waterways

- Custom Towers

- Fiberglass Hardtops and Boxes

- Interior Head Liner

- Cabinet Veneer Layup/Finish

Parts & Components

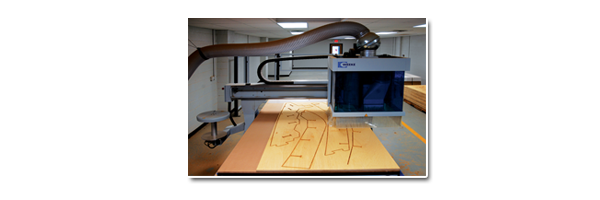

Intensity Boat Works has taken boat building parts and components to the next generation. We have incorporated the ingenuity of the "old school" methods, with the new era of efficient technology and machinery to bring quality parts and components to our customers.

Our machine shaped parts and components take the worries out of tedious and time consuming errors and put it in the hands of our CNC technology. With the help of highly accurate CAM/CAD engineering software and the talent of our hand craftsmen, we have the blend to creatively design custom parts and components to your specifications.

Our in-house CNC router, Weeke BHP 200, machine center is built for both nested sheets of material and 2 1/2 D CAD geometry. We can manufacture materials that include: hard/soft wood, wood composites, hard/soft plastics and aluminum. The router table is set at 12'L x 5'W.

Accompanied with the router is our automatic edgebander, BRANDT KDF 530, which enables us to wrap an edge of permanent material accurately and in a timely manner.

The correlation between our hand craftsmen and CNC technologies gives our customers a major advantage when it comes to reliable quality and time saving efficiencies.